Avalanche Diode Deep Technical Review: High-Voltage Protection & Fast Response

Valanche Diodes – In-Depth Technical Analysis

Name and Physical Essence

In the realm of semiconductor devices, the Avalanche Diode earns its name not by coincidence but by precisely reflecting its operating mechanism. The term “avalanche” refers to the avalanche effect—a phenomenon where, under sufficient reverse bias, minority carriers are accelerated by a strong electric field to the point where they can knock valence electrons out of the crystal lattice, promoting them into the conduction band. These newly generated electron–hole pairs, in turn, are accelerated and cause further collisions, creating more carriers in a chain reaction, much like a small stone triggering a snow avalanche.

This effect requires reverse-biased PN junctions, a sufficiently high electric field, and an appropriately thick depletion region. Unlike the Zener breakdown in low-voltage devices, avalanche breakdown is driven primarily by high-energy carrier impact ionization rather than quantum tunneling. As a result, avalanche breakdown voltages are typically higher (generally >6 V) and exhibit a positive temperature coefficient.

Microscopic Mechanism of the Avalanche Effect

From a microscopic perspective, the avalanche process is well explained by semiconductor energy band theory. Under reverse bias, the PN junction’s depletion region widens, and the electric field intensity increases. When the reverse voltage reaches the breakdown voltage VBR, the field strength is sufficient to accelerate minority carriers to high energies. High-energy electrons colliding with semiconductor atoms can promote valence electrons into the conduction band, generating new electron–hole pairs.

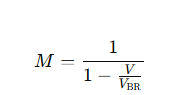

This process, known as impact ionization, exhibits a multiplication effect quantified by the multiplication factor M

Here, Vis the applied reverse voltage. As Vapproaches VBR, M rises sharply, leading to a sudden increase in current. Unlike thermal breakdown, avalanche breakdown is controllable and repeatable, enabling avalanche diodes to operate stably in their breakdown region.

Structural Design of Avalanche Diodes

Manufacturing avalanche diodes involves precisely doped PN junctions, with depletion regions thick enough to ensure that breakdown is dominated by avalanche rather than Zener effects. To prevent localized electric field hotspots that could cause secondary breakdown, manufacturers design passivation layers or use rounded junction geometries to distribute the field evenly.

For high-power applications, large junction areas and metal package designs improve heat capacity and dissipation. In low-power protection circuits, surface-mount (SMD) packages such as DO-214AA or SOD-323 are commonly used, offering low parasitic inductance and fast response in high-speed circuits.

Key Electrical Parameters

When selecting or designing with avalanche diodes, engineers focus on these critical parameters:

Reverse Breakdown Voltage (V_BR) – Specified at a given test current, e.g., V_BR = 20 V at 1 mA.

Peak Pulse Current (I_PP) – The maximum current the diode can handle for a very short duration.

Pulse Power Rating (P_PP) – The maximum energy dissipation capability for a specified pulse width.

Reverse Leakage Current (I_R) – The small leakage under normal reverse operation, which increases significantly at high temperatures.

Response Time (t_rr) – Typically in the nanosecond range, ideal for high-speed signal protection.

It is worth noting that avalanche diodes and TVS diodes are closely related concepts. In fact, many unidirectional TVS diodes are optimized avalanche diodes, with TVS designs emphasizing transient energy absorption and capacitance characteristics.

Engineering Differences Between Avalanche and Zener Diodes

While both operate stably in reverse breakdown, their physics, characteristics, and applications differ:

Breakdown Mechanism – Zener diodes rely on quantum tunneling; avalanche diodes rely on impact ionization.

Voltage Range – Zener: 3–5 V low-voltage regulation; Avalanche: >6 V high-voltage protection.

Temperature Coefficient – Zener: negative; Avalanche: positive.

Power Handling – Avalanche diodes handle higher transient energy loads.

In practical design, Zener diodes are preferred for low-voltage regulation, avalanche diodes for high-voltage protection, and hybrid designs may use both.

Application Scenarios and Circuit Examples

Overvoltage protection is the most common use case. When a circuit experiences a transient surge—such as power switch inrush or inductive kickback—the avalanche diode quickly enters breakdown, clamping voltage and converting excess energy into heat, thereby safeguarding downstream components.

A typical circuit is MOSFET drain protection: when switching inductive loads (relays, motors), the drain voltage can spike sharply; an avalanche diode limits this to a safe level.

Signal clamping is another important use case, particularly in high-speed data lines (USB, HDMI, Ethernet), where avalanche diodes protect against electrostatic discharge (ESD) or surge interference without significantly degrading signal integrity.

In RF front-end protection, the diode’s low junction capacitance is crucial—it protects sensitive receivers without impairing RF performance.

Failure Modes of Avalanche Diodes

Although avalanche breakdown is controllable, excessive or frequent triggering can cause thermal breakdown, where junction temperatures exceed material limits, permanently degrading performance.

Another risk is secondary breakdown, common in power transistors, where uneven current distribution creates localized hotspots that can quickly destroy the junction.

Designs should maintain adequate safety margins—pulse power should not exceed 70% of the rated value—and use PCB layouts that optimize heat dissipation.

Future Development Trends

With the advancement of power electronics and high-speed communication, avalanche diodes are evolving in several directions:

New Materials – Silicon carbide (SiC) and gallium nitride (GaN) devices offer higher breakdown field strengths, enabling kilovolt-class avalanche diodes.

High-Speed Integrated Protection – Integrating avalanche protection directly into driver ICs for smaller size and faster response.

Low Capacitance Designs – Optimized for 5G, satellite communications, and other high-frequency applications, reducing parasitic capacitance to maintain bandwidth.