Definition and application of stepper motor

1.Stepper motor definition

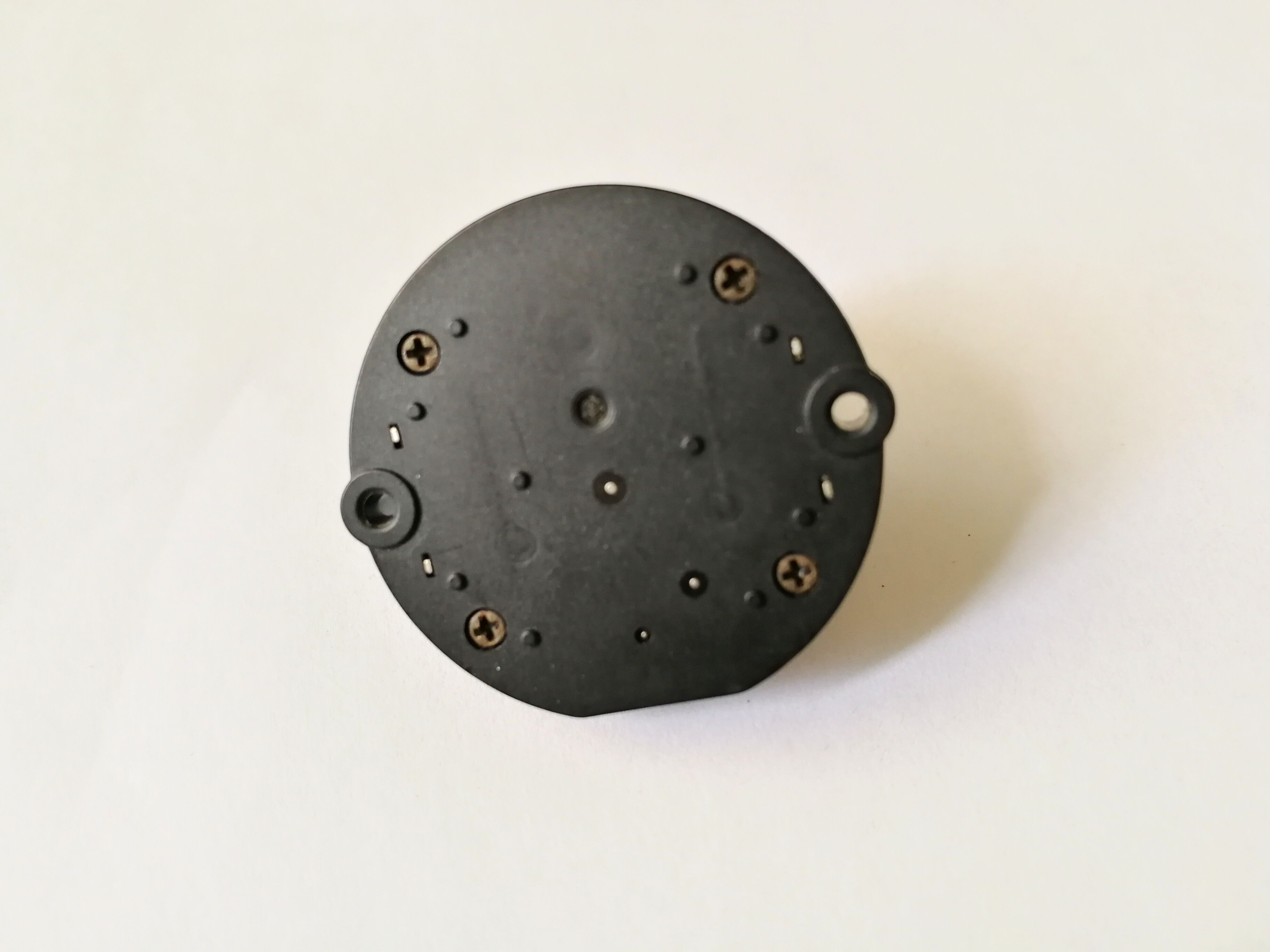

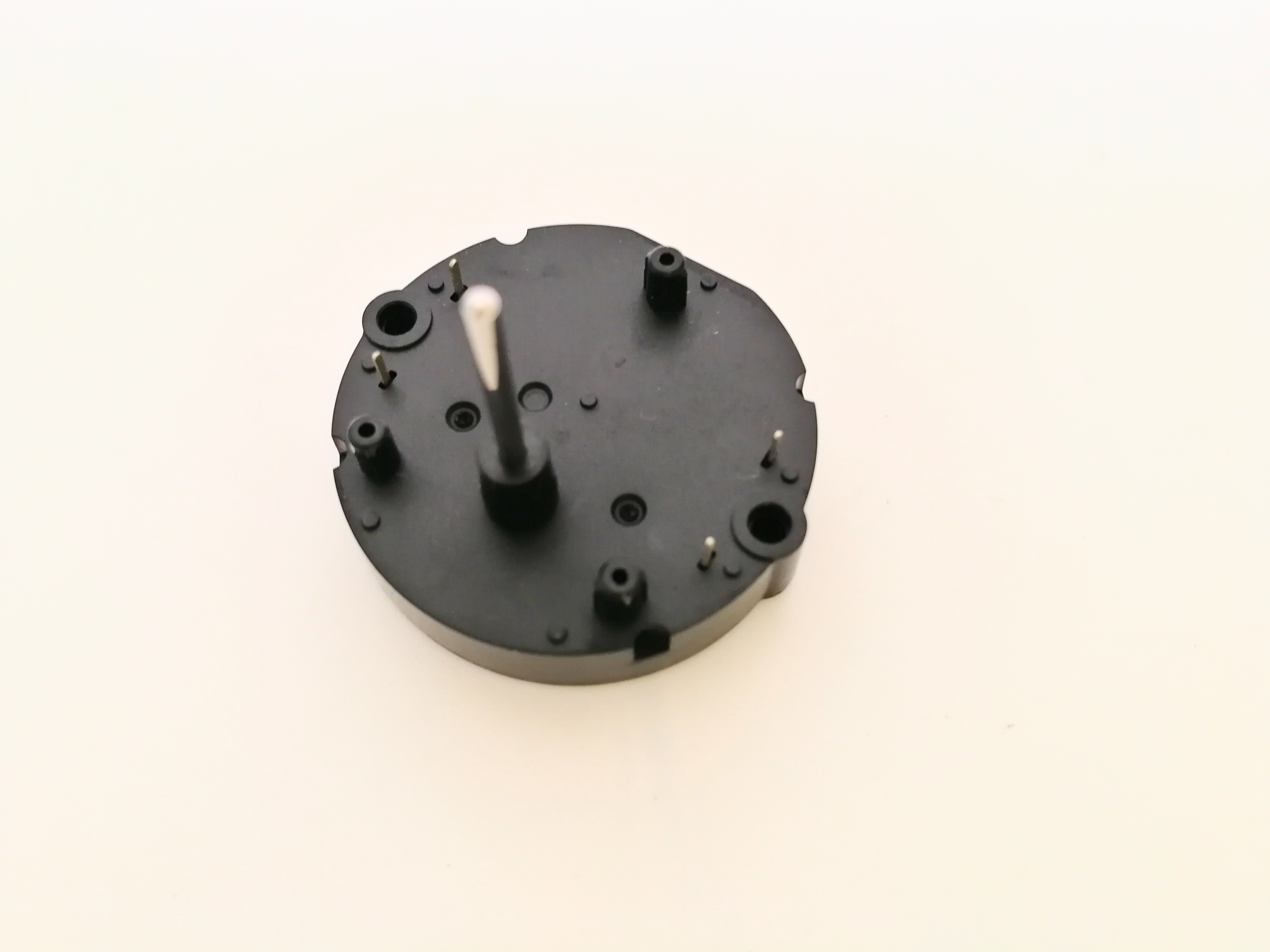

This article is mainly to provide you to the basics of stepper motors. So what is a stepper motor? The definition of a stepping motor is actually an

open-loop control element stepping motor component that converts an electrical pulse signal into an angular displacement or a linear displacement. In the

case of non-overload, the speed and stop position of the motor depends only on the frequency of the pulse signal and the number of pulses, and are not

affected by the load change. When the stepper driver receives a pulse signal, it drives the stepper motor. Rotate a fixed angle in the set direction, called the

"step angle", whose rotation is performed step by step at a fixed angle. It can control the angular displacement by monitoring the number of pulses to

achieve the purpose of accurate positioning. At the same time, the speed and acceleration of the motor rotation can be checked by controlling the pulse

frequency to achieve the purpose of speed regulation.

2. Stepper motor applications

After understanding the definition of a stepper motor, let's think about the main application of stepper motor. As an actuator, stepper motor is part of the

key products of mechatronics and is widely used in various automation control systems. Most of the stepping motors currently used in computerized

embroidery machines are three-phase hybrid stepping motors, and the subdivision driving technology can greatly improve the running quality of stepping

motors, reduce the torque ripple, suppress oscillation, reduce noise, and improve steps. Moment resolution.

First, the stepper motor is mainly used in some occasions to positioning requirements, such as: wire cutting workbench drag, planting machine workbench

(pores positioning), packaging machine (fixed length), basically involving positioning occasions Use it.

Second, it is widely used in ATM machines, inkjet printers, cutting plotters, photo machines, spraying equipment, medical instruments and equipment,

computer peripherals and mass storage equipment, precision instruments, industrial control systems, office automation, robots, etc. Applications requiring

smooth operation, low noise, fast response, long life and high output torque.

Third, the stepping motor is under a wide range of applications in textile machinery such as computer embroidery machines. The characteristics of this

type of stepping motor are that the torque is not high, the reaction speed is fast, the running noise is low, the operation is stable, and the control performance

is good. The whole machine costs are depleted.

With the development of microelectronics and computer technology, the demand for stepper motors is increasing day by day, and it has applications in

numerous national economic fields.

3. Stepper motor application notes

① Stepper motor is used in low-speed occasions---the speed per minute does not exceed 1000 rpm, (6666PPS at 0.9 degrees), preferably between

1000-3000PPS (0.9 degrees), which can be utilized to work here through the reduction gear. At this time, the motor has high working efficiency and low

noise.

② Stepper motors are best not to use the whole step state. The vibration is large in the whole step state.

③ Due to historical reasons, only the motor with the nominal 12V voltage uses 12V. The voltage value of other motors is not the driving voltage volt value.

The driving voltage can be chosen according to the driver. (Recommended: 57BYG uses DC 24V-36V, 86BYG uses DC 50V, 110BYG Use more than DC

80V), of course, 12 volts in addition to 12V constant voltage drive can also use other drive power, but consider the temperature rise.

④ The load with a large moment of inertia should select the motor of large frame size.

⑤ When the motor is at a high speed or a large inertia load, it is generally not started at the working speed, but the gradual up frequency is used to speed

up, one motor does not lose the step, and the second can reduce the noise and improve the positioning accuracy of the stop.

⑥ When high precision is used, it should be resolved by mechanical deceleration, increasing the speed of the motor, or by using a driver with high

subdivision number. It is also possible to utilize a 5-phase motor, but the whole system is more expensive, fewer manufacturers, and it is eliminated. The

argument is a layman.

⑦ The motor should not work in the vibration zone. If it must be resolved by changing the voltage, current or adding some damping.

⑧ The motor works below 600PPS (0.9 degrees) and should be guided by small current, large inductance and low voltage.

⑨should follow the principle of selecting the motor after selecting the motor.

Stepper motors are often found in our daily lives, such as air-conditioning sweeps, printer applications, robot walks, etc., the drive must have a drive signal

to operate, and the drive signal is a pulse signal, stepping, as the name suggests, step by step. If there is no pulse, the stepper motor will not run, and the

speed of its operation is proportional to the frequency of the pulse. I hope the basic knowledge about stepper motors can help you.