Fire in Renesas factory destroyed 11 equipment and 5% of space

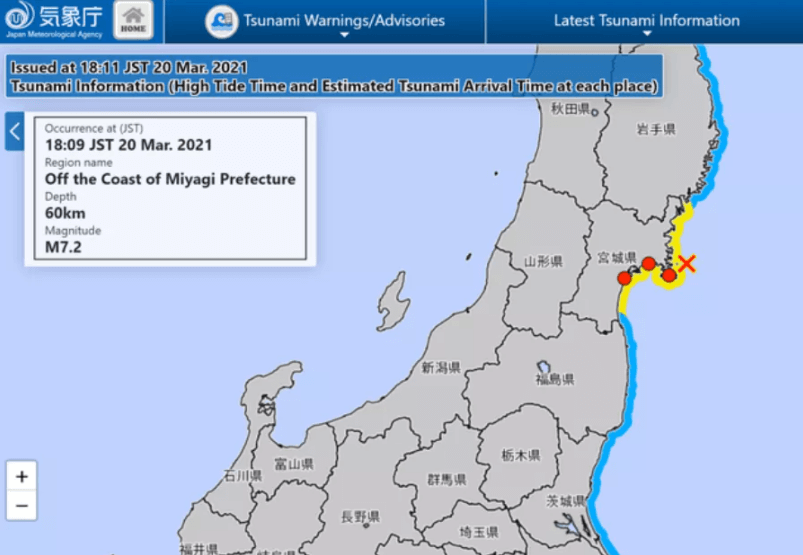

On March 20, CCTV and other media reported that at around 18:09 local time on Saturday in Japan, a standard earthquake of 5 degrees (maximum 7 degrees) and a magnitude of 7.2 on the Richter scale occurred in the waters near Miyagi Prefecture, Japan. The Japan Meteorological Agency predicted that the focal depth was 60 kilometers, and issued a tsunami warning to the sea near Miyagi Prefecture, and the height is expected to reach 1 meter.

The earthquake occurred only a few days after the "10th anniversary of the March 11 earthquake". The tsunami caused by the earthquake also severely damaged Miyagi Prefecture and caused an accident at the neighboring Fukushima Nuclear Power Plant.

In the middle of last month, an earthquake measuring 7.3 on the Richter scale also occurred in the offshore area of Fukushima Prefecture, and strong earthquakes of 6 magnitude were observed in Fukushima and Miyagi prefectures. Officials from the Japan Meteorological Agency called the Fukushima earthquake an aftershock of the 2011 “March 11th Earthquake”. According to Japanese media reports, despite large-scale power outages and water cuts in many parts of Japan, no abnormalities were found at the Fukushima No. 1 and No. 2 nuclear power plants.

As for the semiconductor market, the impact caused by the Fukushima earthquake last month may be staged again. Japan’s Renesas, the world’s third-largest automotive chip manufacturer, has a chip factory in Ibaraki Prefecture. After the earthquake in February, it halted for two weeks to confirm whether the production equipment is in good condition. Since the plant also suffered a fire on Friday, the impact of the earthquake on Saturday may further delay the timetable for resuming production. In addition, Fujitsu, capacitor manufacturer NEC TOKIN, and Toyota Motor also have production facilities in Miyagi or Fukushima Prefecture.

The "fire" of the Renesas factory destroyed 11 equipment and 5% of the space

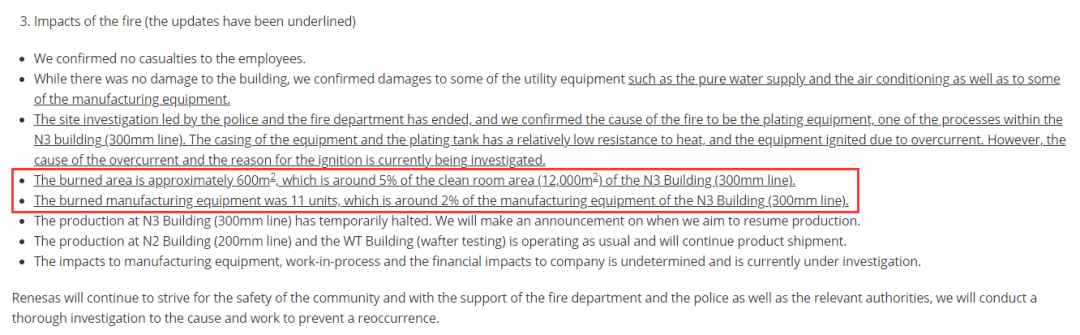

On March 20, Renesas Electronics issued a notice stating that on March 19, Renesas Electronics’ NAKA plant in Ibaraki Prefecture, Japan suffered a fire and the 12-inch production line on the 1st floor of the N3 building was suspended. According to the latest official report from Renesas, the cause of the fire was that the electroplating equipment caught fire due to electric current, which caused the 600 square meters of clean room on the 1st floor of the N3 building to be burned, accounting for 5% of the total space, and 11 manufacturing equipment were damaged, accounting for about the total manufacturing equipment. 2%.

Fortunately, no casualties were caused, and the 8-inch production line on the N2 building was not affected by the fire. The WT building (wafer testing) is producing normally and will continue to deliver products.

The global chip shortage, including automotive chips, is also in short supply. Due to the increase in raw material and packaging costs, some of Renesas’ analog and power products will increase their prices from January 1, 2021, and all existing and new orders thereafter will also All are dealt with at the new price. Recently, Renesas Electronics also warned that it is estimated that the global automotive chip shortage problem may continue into the second half of the year, and it is uncertain when the market supply and demand will return to balance.

According to previous information, the earthquake in Japan at the beginning of this year has caused Renesas' chip factory to suspend production for nearly half a month. Renesas Automotive’s advanced manufacturing processes for SoC and MCU chips use 16nm and 28nm, respectively, but in order to meet the needs of automotive chips, the NAKA factory’s standby production line uses a 40nm process because mature technology is used in automobiles to ensure safety features and security. Recently, Renesas Electronics has converted some of the semiconductors previously entrusted to external production such as TSMC to its own internal production due to insufficient automotive semiconductors. It is worth mentioning that the factory building where the fire broke out is mass production of cutting-edge products handed over from TSMC. If production continues to stop, the impact on the supply of automotive semiconductor chips may continue to expand.

In addition, Renesas Electronics executives warned last week that the global shortage of automotive semiconductor supplies may continue into the second half of the year. Like other industry leaders, Renesas Electronics is also preparing to deal with the impact of chip shortages on the production of automobiles and electronic products, and this impact will continue beyond the summer.

To make the automotive industry chip supply worse, the extremely cold weather in Texas in the United States in mid-to-late February of this year caused local water and power outages. The two plants of NXP (NXP), the world’s largest automotive chip manufacturer, halted production. The local production bases of the two major chip manufacturers Samsung Electronics and automotive chip manufacturer Infineon may also face production suspensions.